Ing wiwitan produksi logam otomatis, pamilik bisnis biasane luwih seneng tuku meja plasma CNC utami utawa mesin pemotong waterjet kanggo ngethok logam sing kandel, lan pemotong plasma CNC sing apik kanggo ngethok logam tipis. Kanthi kabutuhan keamanan manufaktur lan perlindungan lingkungan ing pabrik logam, YAG lan CO2 mesin nglereni laser padha ngenalaken ing pasar, kang nggawa kualitas nglereni logam kanggo tingkat anyar. Kajaba iku, laser luwih ramah lingkungan lan luwih aman tinimbang plasma lan waterjet, lan ora mbutuhake bahan bakar. Nanging, loro laser YAG lan karbon dioksida duwe watesan dhewe, kayata biaya investasi dhuwur, kekandelan nglereni winates, lan malah kacepetan sing ora apik minangka plasma. Ing wektu iki, jinis anyar sistem nglereni logam laser diluncurake, yaiku laser serat. Iki minangka mesin pemotong logam profesional. Apa kualitas, kacepetan utawa kekandelan, minangka owah-owahan daya laser, wis tekan dhuwur unprecedented. Fitur lan kaluwihan presisi dhuwur, kualitas dhuwur, kacepetan cepet, biaya murah, gampang digunakake, lan otomatisasi lengkap nggawe unicorn ing tabung lan pabrikan lembaran logam.

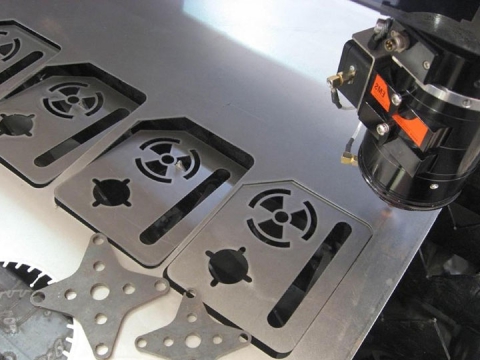

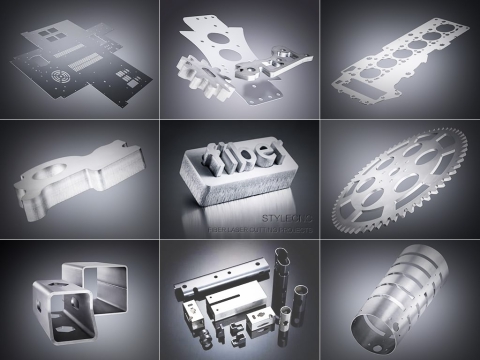

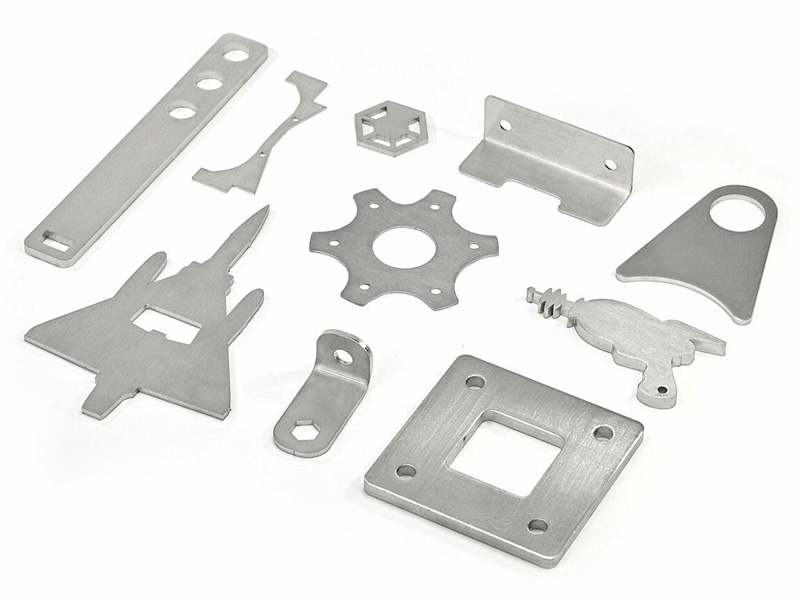

Pemotong laser serat minangka jinis anyar sistem pemotongan logam kanthi tliti dhuwur sing nggunakake pengontrol CNC kanggo nyopir sirah laser kanggo motong logam kanthi file tata letak sing dirancang kanggo ngotomatisasi fabrikasi logam ing bisnis cilik lan manufaktur industri. saka 1mm stainless steel, kanggo liwat 100mm baja karbon, lan malah logam Highly reflektif kayata Kuningan, tembaga, aluminium, emas, lan salaka, iku bisa gampang Cut liwat kanggo nggawe kontur Gamelan karo gas apa beda kalebu online, nitrogen lan oksigen. Apa iku sheet metal, tabung utawa profil khusus, mesin serat laser nduweni kemampuan kanggo Cut metu wangun pas lan resik.

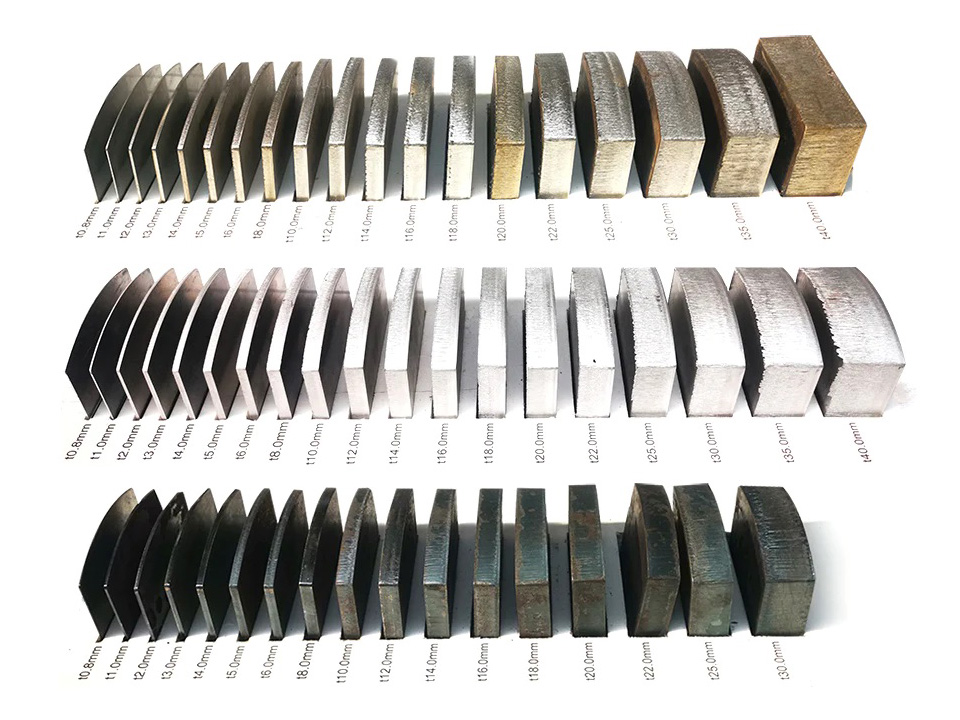

Ngadhepi alat nglereni sing kuat, sampeyan kepingin weruh kepiye logam bisa dipotong? Apa watesan kacepetan nglereni? Carane nindakake macem-macem daya laser ing nglereni kekandelan logam lan kacepetan? Iki minangka pandhuan praktis kanggo pamula lan ahli, ngidini kita nggawe analisis rinci saka macem-macem bahan logam, gas kerja, kekuwatan laser, ketebalan lan kecepatan pemotongan.

Fiber Laser Cutting Carbon Steel Ketebalan & Kacepetan & Power Chart

Baja karbon minangka paduan wesi-karbon kanthi kandungan karbon antara 0.02% lan 2%.

Baja karbon sing bisa dipotong laser serat kalebu baja karbon rendah (baja ringan), baja karbon medium (baja M2) lan baja karbon dhuwur (baja alat).

pemotong laser serat bisa gampang Cut baja karbon kiro-kiro saka 1mm kanggo liwat 200mm ing kacepetan saka 0.12m / min kanggo 100m/ min, karo kakuwasan opsional miwiti saka 1000W lan nganti 60000W, lan opsi gas sing digunakake kalebu udara, oksigen, nitrogen lan gas campuran.

Daya Sedheng/Sedheng (1000W - 4000W) Parameter Pemotongan Baja Karbon

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| Karbon Baja | Air | 1 | 12.0-15.0 | 15.0-20.0 | 25.0-30.0 | 28.0-35.0 | 30.0-38.0 |

| 2 | 3.5-4.5 | 5.0-8.0 | 7.0-10.0 | 8.0-12.0 | 10.0-16.0 | ||

| 3 | 1.5-3.0 | 2.0-4.0 | 2.5-4.5 | 3.0-5.0 | |||

| 4 | 1.5-2.3 | 2.5-3.5 | |||||

| 5 | 1.0-2.2 | ||||||

| N₂ | 1 | 15.0-20.0 | 18.0-25.0 | 22.0-30.0 | 25.0-38.0 | 30.0-44.0 | |

| O₂ | 2 | 3.5-5.0 | 3.8-5.0 | 5.0-6.0 | 5.5-7.0 | 5.5-7.7 | |

| 3 | 2.5-3.5 | 2.8-3.8 | 3.5-4.3 | 3.6-5.0 | 3.7-5.5 | ||

| 4 | 2.0-3.3 | 2.3-3.5 | 2.8-4.0 | 3.0-4.5 | 3.5-4.6 | ||

| 5 | 1.4-2.0 | 1.6-2.5 | 2.5-3.0 | 2.5-3.3 | 2.5-4.0 | ||

| 6 | 1.2-1.6 | 1.4-1.8 | 2.2-2.5 | 2.3-2.8 | 2.5-3.5 | ||

| 8 | 0.8-1.1 | 0.9-1.3 | 1.3-1.8 | 1.8-2.2 | 2.0-2.8 | ||

| 10 | 0.6-0.9 | 0.8-1.2 | 1.2-1.5 | 1.2-1.6 | 1.2-2.2 | ||

| 12 | 0.4-0.7 | 0.7-1.0 | 0.8-1.0 | 1.0-1.3 | 1.0-1.7 | ||

| 16 | 0.5-0.7 | 0.6-0.8 | 0.6-0.9 | 0.7-1.0 | |||

| 20 | 0.5-0.8 | 0.6-0.9 | |||||

| 22 | 0.5-0.8 | ||||||

Daya dhuwur (6000W - 30000W) Parameter Pemotongan Baja Karbon

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| Karbon Baja | Air | 1 | 35.0-42.0 | 38.0-45.0 | 45.0-60.0 | 50.0-70.0 | 60.0-100.0 | 70.0-100.0 |

| 2 | 20.0-28.0 | 25.0-35.0 | 35.0-48.0 | 45.0-52.0 | 50.0-70.0 | 60.0-73.0 | ||

| 3 | 8.0-15.0 | 18.0-25.0 | 25.0-38.0 | 30.0-40.0 | 45.0-52.0 | 50.0-57.0 | ||

| 4 | 7.0-12.0 | 15.0-18.0 | 18.0-26.0 | 25.0-29.0 | 30.0-40.0 | 35.0-43.0 | ||

| 5 | 5.0-9.0 | 10.0-12.0 | 12.0-20.0 | 18.0-23.0 | 23.0-28.0 | 25.0-30.0 | ||

| 6 | 3.0-6.0 | 8.0-9.0 | 9.0-13.0 | 13.0-19.0 | 18.0-23.0 | 19.0-26.0 | ||

| 8 | 5.0-5.5 | 6.0-8.0 | 8.0-12.0 | 12.0-16.0 | 14.0-18.0 | |||

| 10 | 5-6.5 | 6.0-8.5 | 11.0-13.0 | 12.0-14.0 | ||||

| 12 | 4.0-4.6 | 5.0-6.0 | 7.0-10.0 | 10.0-12.0 | ||||

| 16 | 4.5-5.5 | 6.5-7.0 | 8.0-8.5 | |||||

| 20 | 2.7-3.2 | 4.5-5.5 | ||||||

| 22 | 2.9-3.5 | |||||||

| 25 | 2.0-3.2 | |||||||

| N₂ | 1 | 35.0-48.0 | 60.0-70.0 | 66.0-80.0 | 70.0-90.0 | 80.0-95.0 | 95.0-100.0 | |

| O₂ | 2 | 6.0-8.25 | 6.8-7.2 | 7.2-7.8 | 7.5-8.2 | 7.8-8.5 | 8.0-10.0 | |

| 3 | 4.0-5.5 | 4.8-5.5 | 5.2-5.8 | 5.5-6.0 | 5.8-6.3 | 6.0-7.0 | ||

| 4 | 3.5-5.0 | 3.8-4.3 | 4.2-4.6 | 4.5-5.2 | 4.8-5.5 | 5.0-6.5 | ||

| 5 | 3.0-4.2 | 3.3-4.3 | 3.8-4.7 | 4.0-5.0 | 4.3-4.8 | 4.5-5.0 | ||

| 6 | 2.6-3.5 | 3.0-3.4 | 3.5-4.0 | 3.8-4.3 | 4.0-4.5 | 4.2-4.8 | ||

| 8 | 2.0-2.8 | 2.3-3.0 | 2.6-3.3 | 2.8-3.5 | 3.0-3.6 | 3.5-4.0 | ||

| 10 | 1.8-2.3 | 2.0-2.5 | 2.5-3.0 | 2.6-3.0 | 2.8-3.2 | 3.0-3.5 | ||

| 12 | 1.6-2.1 | 1.7-2.2 | 2.0-2.3 | 2.5-3.0 | 2.7-3.2 | 2.8-3.4 | ||

| 16 | 0.7-1.0 | 1.2-1.4 | 1.4-1.6 | 1.7-2.0 | 1.9-2.3 | 2.0-2.5 | ||

| 20 | 0.5-0.9 | 1.0-1.1 | 1.2-1.5 (2.1) | 1.3-1.6 | 1.5-1.8 | 1.6-2.0 | ||

| 22 | 0.5-0.7 | 0.9-1.0 | 0.9-1.2 | 1.1-1.3 | 1.3-1.6 | 1.5-1.8 | ||

| 25 | 0.4-0.6 | 0.6-0.7 | 0.6-0.9 | 0.9-1.2 | 1.0-1.4 | 1.3-1.5 | ||

| 30 | 0.3-0.6 | 0.5-0.8 | 0.6-0.8 | 0.8-1.2 | 1.2-1.4 | |||

| 40 | 0.25-0.33 | 0.4-0.7 | 0.7-0.9 | 0.9-1.1 | ||||

| 50 | 0.18-0.2 | 0.2-0.25 | 0.3-0.5 | 0.6-0.8 | ||||

| 60 | 0.18-0.2 | 0.2-0.25 | 0.22-0.28 | |||||

| 70 | 0.18-0.2 | 0.19-0.22 | ||||||

| 80 | 0.12-0.15 | |||||||

Daya Ekstra Dhuwur (40000W) Parameter Pemotongan Baja Karbon

| Material | Kekandelan (mm) | Kacepetan (m/min) | Daya (watt) | Gas Kerja |

|---|---|---|---|---|

| Karbon Baja | 5 | 28.0-32.0 | 40000 | N₂ / Air |

| 6 | 25.0-28.0 | |||

| 8 | 22.0-24.0 | |||

| 10 | 16.0-20.0 | |||

| 12 | 14.0-17.0 | |||

| 14 | 11.0-13.0 | |||

| 16 | 8.0-9.5 | |||

| 18 | 8.0-8.5 | |||

| 20 | 7.0-8.0 | |||

| 25 | 5.0-5.5 | |||

| 30 | 3.0-4.0 | |||

| 40 | 1.5-2.0 | |||

| 50 | 0.7-1.0 | |||

| 10 | 2.0-2.3 | 6000 | O₂ (Fokus Positif) | |

| 12 | 1.8-2.0 | 7,500 | ||

| 14 | 1.6-1.8 | 8,500 | ||

| 16 | 1.6-1.8 | 9,500 | ||

| 20 | 1.5-1.6 | 12000 | ||

| 22 | 1.4-1.5 | 18000 | ||

| 25 | 1.2-1.4 | 18000 | ||

| 30 | 1.2-1.3 | 18000 | ||

| 40 | 0.9-1.1 | 26000 | ||

| 40 (Non-Q235) | 0.3-0.6 | 20000 | ||

| 50 (Non-Q235) | 0.3-0.5 | 25000 | ||

| 50 | 0.8-1.0 | 40000 | ||

| 60 | 0.6-0.9 | |||

| 70 | 0.5-0.7 | |||

| 80 | 0.4-0.6 | |||

| 90 | 0.3-0.4 | |||

| 100 | 0.2-0.3 | |||

| 12 | 3.2-3.5 | 20000 | O₂ (Fokus Negatif) | |

| 14 | 3.0-3.2 | |||

| 16 | 3.0-3.1 | |||

| 20 | 2.8-3.2 | |||

| 25 | 2.4-2.8 | 40000 | ||

| 30 | 2.4-2.6 | |||

| 35 | 2.3-2.6 | |||

| 40 | 2.0-2.3 | |||

| 50 | 1.2-1.6 | |||

| 60 | 1.0-1.3 | |||

| 70 | 0.6-0.8 |

Daya Ultra-Dhuwur (60000W) Parameter Pemotongan Baja Karbon

| Material | Kekandelan (mm) | Kacepetan (m/min) | Daya (watt) | Gas Kerja |

|---|---|---|---|---|

| Karbon Baja | 16 | 13.0-14.0 | 60000 | Campuran Gas - (N₂&O₂)/Udara |

| 18 | 11.0-12.0 | |||

| 20 | 9.0-10.0 | |||

| 25 | 6.5-7.5 | |||

| 30 | 4.5-5.5 | |||

| 35 | 3.5-4.4 | |||

| 40 | 2.8-3.4 | |||

| 45 | 2.0-2.5 | |||

| 50 | 1.5-2.0 | |||

| 60 | 1.0-1.4 | |||

| 16 | 1.6-1.8 | 12000 | O₂ (Fokus Positif) | |

| 18 | 1.6-1.7 | |||

| 20 | 1.5-1.6 | |||

| 25 | 1.2-1.4 | 20000 | ||

| 30 | 1.2-1.3 | |||

| 35 | 1.1-1.2 | |||

| 40 | 0.9-1.1 | 25000 | ||

| 45 | 0.8-1.0 | |||

| 50 | 0.75-0.9 | 30000 | ||

| 60 | 0.7-0.8 | 50000 | ||

| 70 | 0.7-0.8 | 60000 | ||

| 80 | 0.6-0.7 | |||

| 100 | 0.5-0.6 | |||

| 160 | 0.15-0.25 | |||

| 200 | 0.15-0.2 | |||

| 20 | 2.4-3.0 | 15000 | O₂ (Fokus Negatif) | |

| 25 | 2.2-2.6 | 30000 | ||

| 30 | 2.0-2.4 | |||

| 35 | 2.0-2.2 | 35000 | ||

| 40 | 1.6-2.0 | |||

| 45 | 1.4-1.8 | 40000 | ||

| 50 | 1.2-1.6 | |||

| 60 | 1.0-1.3 | 60000 | ||

| 70 | 1.0-1.2 | |||

| 80 | 0.8-1.0 | |||

| 100 | 0.5-0.65 |

Fiber Laser Cutting Stainless Steel Ketebalan & Kacepetan & Power Chart

Baja tahan karat nuduhake baja paduan sing pasif, tahan korosi, ora karat, lan ngandhut kromium dhuwur (biasane 12%~30%) ing atmosfer lan media korosif kayata asam, alkali, lan uyah, sing ngandhut nikel, molybdenum, vanadium, manganese, tungsten lan unsur liyane, uga dikenal minangka baja tahan asam, wesi putih, wesi tembaga banyu.

Ing ASTM gelar lan model saka stainless steel sing laser serat bisa Cut kalebu 201, 202, 205, 301, 302, 302B, 302Cu, 303, 304, 304L, 304N, 305, 308, 309, 310, 314, 316L, 316, 316L, 317 317L, 321, 329, 330, 347, 384, 403, 405, 409, 410, 414, 416, 420, 422, 429, 430, 430F, 431, 434, 436, 439 (A) 440 440B, 44C ), 0, 440, 444, 446, 501L lan 502.

Mesin nglereni serat laser bisa nglereni baja tahan karat tipis nganti 1 milimeter lan kandel nganti 150 milimeter kanthi kecepatan 0.05 meter per menit lan nganti 100 meter per menit, kanthi kekuwatan laser wiwit saka 1000W kanggo 60000W, lan gas kerja opsional saka N₂ lan Udara.

Daya Sedheng/Sedheng (1000W - 4000W) Parameter Pemotongan Stainless Steel

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| Steel | Air | 1 | 15.0-25.0 | 18.0-30.0 | 20.0-35.0 | 32.0-40.0 | 35.0-50.0 |

| 2 | 4.0-7.0 | 8.0-12.0 | 10.0-15.0 | 14.0-18.0 | 16.0-23.0 | ||

| 3 | 2.5-3.5 | 3.0-4.0 | 5.0-7.0 | 8.0-12.0 | 8.0-14.0 | ||

| 4 | 0.6-1.0 | 2.0-3.0 | 3.5-4.5 | 5.5-8.0 | 6.0-10.0 | ||

| 5 | 0.5-0.8 | 1.2-1.8 | 1.8-2.5 | 3.5-5.0 | 4.5-6.0 | ||

| 6 | 0.5-0.8 | 0.7-0.8 | 2.5-3.0 | 2.8-4.8 | |||

| 8 | 0.5 | 1.2-1.5 | 1.8-3.0 | ||||

| 10 | 0.8-1.2 | 0.85-1.8 | |||||

| 12 | 0.65-1.0 | ||||||

| N₂ | 1 | 16.5-22.0 | 20.0-26.0 | 27.5-33.0 | 31.0-38.5 | 33.0-45.0 | |

| 2 | 4.5-6.1 | 7.0-10.0 | 9.0-11.0 | 12.0-16.5 | 15.0-20.0 | ||

| 3 | 2.0-3.1 | 4.5-5.5 | 5.0-6.5 | 7.0-10.0 | 7.5-12.0 | ||

| 4 | 1.0-1.6 | 2.0-2.5 | 2.2-2.8 | 5.0-7.2 | 5.5-9.0 | ||

| 5 | 0.4-0.7 | 1.5-2.0 | 1.5-2.0 | 1.8-2.4 | 4.0-5.5 | ||

| 6 | 0.6-0.9 | 0.7-1.3 | 1.0-1.6 | 2.6-4.5 | |||

| 8 | 0.3-0.6 | 1.2-2.0 | 1.6-2.8 | ||||

| 10 | 0.7-1.0 | 0.7-1.6 | |||||

| 12 | 0.5-0.9 | ||||||

Daya dhuwur (6000W - 30000W) Parameter Pemotongan Stainless Steel

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| Steel | Air | 1 | 55.0-70.0 | 65.0-75.0 | 70.0-85.0 | 80.0-95.0 | 83.0-100.0 | 85.0-100.0 |

| 2 | 32.0-45.0 | 40.0-50.0 | 45.0-55.0 | 48.0-55.0 | 55.0-70.0 | 65.0-80.0 | ||

| 3 | 20.0-28.0 | 27.0-33.0 | 30.0-38.0 | 35.0-40.0 | 45.0-52.0 | 55.0-60.0 | ||

| 4 | 13.0-18.0 | 15.0-20.0 | 25.0-30.0 | 25.0-29.0 | 30.0-40.0 | 38.0-45.0 | ||

| 5 | 10.0-15.0 | 12.0-16.0 | 16.0-19.0 | 18.0-23.0 | 23.0-28.0 | 27.0-33.0 | ||

| 6 | 7.0-10.0 | 9.0-11.0 | 13.0-17.0 | 14.0-19.0 | 18.0-23.0 | 24.0-28.0 | ||

| 8 | 4.5-6.0 | 5.5-6.0 | 9.0-11.0 | 8.0-12.0 | 14.0-16.0 | 20.0-24.0 | ||

| 10 | 2.0-3.0 | 4.0-4.5 | 6.5-8.0 | 6.8-8.5 | 9.0-12.0 | 15.0-20.0 | ||

| 12 | 1.4-1.8 | 2.5-3.5 | 5.5-6.0 | 5.5-6.5 | 8.0-10.0 | 12.5-15.0 | ||

| 16 | 0.8-1.0 | 1.3-2.0 | 2.2-2.8 | 4.5-5.5 | 5.5-6.5 | 8.0-9.0 | ||

| 20 | 0.5 | 0.7-1.0 | 1.5-2.0 | 1.9-2.1 | 2.7-3.2 | 4.5-5.5 | ||

| 25 | 0.5-0.8 | 0.8-1.2 | 1.2-1.4 | 1.8-2.5 | 2.5-3.0 | |||

| 30 | 0.25-0.4 | 0.5-0.8 | 0.8-1.0 | 1.4-1.6 | 1.5-2.2 | |||

| 40 | 0.4-0.5 | 0.5-0.8 | 0.8-1.0 | |||||

| 50 | 0.17-0.3 | 0..3-0.4 | 0.3-0.45 | |||||

| 60 | 0.14-0.18 | 0.16-0.2 | ||||||

| 70 | 0.1-0.13 | 0.1-0.15 | ||||||

| 80 | 0.05 | |||||||

| N₂ | 1 | 50.0-65.0 | 63.0-66.0 | 70.0-80.0 | 75.0-90.0 | 80.0-100.0 | 82.0-100.0 | |

| 2 | 30.0-40.0 | 40.0-44.0 | 44.0-48.0 | 46.0-50.0 | 50.0-60.0 | 63.0-75.0 | ||

| 3 | 18.0-25.0 | 25.0-28.0 | 28.0-35.0 | 30.0-38.0 | 35.0-45.0 | 52.0-58.0 | ||

| 4 | 10.0-15.5 | 15.0-18.0 | 20.0-26.0 | 22.0-28.0 | 30.0-32.0 | 35.0-43.0 | ||

| 5 | 8.0-13.5 | 12.0-14.0 | 15.0-20.0 | 16.0-22.0 | 24.0-28.0 | 25.0-30.0 | ||

| 6 | 6.0-9.0 | 9.0-9.5 | 11.0-13.0 | 12.0-15.0 | 20.0-25.0 | 22.0-25.0 | ||

| 8 | 4.0-5.5 | 5.0-5.3 | 7.0-7.5 | 7.5-8.5 | 14.0-17.0 | 18.0-22.0 | ||

| 10 | 1.8-2.8 | 3.8-4.0 | 5.0-5.5 | 5.5-6.5 | 10.0-13.0 | 14.0-18.0 | ||

| 12 | 1.2-1.6 | 2.5-2.7 | 3.0-3.5 | 3.3-4.0 | 9.0-10.0 | 12.0-14.0 | ||

| 14 | 0.8-1.2 | 1.8-1.9 | 2.3-2.8 | 2.5-3.0 | 7.0-8.5 | 8.0-10.0 | ||

| 16 | 0.6-0.9 | 1.3-1.5 | 2.1-2.5 | 2.3-2.8 | 5.0-6.0 | 7.0-8.0 | ||

| 20 | 0.7-0.8 | 1.4-1.7 | 1.5-1.9 | 2.5-3.0 | 4.0-5.0 | |||

| 25 | 0.5-0.6 | 0.7-1.0 | 0.9-1.2 | 1.4-1.8 | 2.0-2.5 | |||

| 30 | 0.5-0.7 | 0.6-0.8 | 0.9-1.2 | 1.2-2.0 | ||||

| 35 | 0.4-0.5 | 0.5 | 0.55-0.8 | 0.7-1.0 | ||||

| 40 | 0.3 | 0.4 | 0.4-0.5 | 0.6-0.8 | ||||

| 50 | 0.2 | 0.25 | 0.3-0.35 | 0.3-0.4 | ||||

| 60 | 0.15 | 0.15-0.2 | 0.15-0.25 | |||||

| 70 | 0.1-0.13 | 0.12-0.15 | ||||||

| 80 | 0.06-0.08 | 0.08-0.1 | ||||||

| 90 | 0.05-0.06 | 0.5-0.08 | ||||||

| 100 | 0.03-0.04 | 0.04-0.05 | ||||||

Daya Ekstra Dhuwur (40000W) Parameter Pemotongan Stainless Steel

| Material | Kekandelan (mm) | Kacepetan (m/min) | Daya (watt) | Gas Kerja |

|---|---|---|---|---|

| Steel | 5 | 25.0-30.0 | 40000 | N₂ |

| 6 | 22.0-25.0 | |||

| 8 | 20.0-23.0 | |||

| 10 | 16.0-21.0 | |||

| 12 | 12.0-14.0 | |||

| 14 | 10.0-12.0 | |||

| 16 | 9.0-11.0 | |||

| 18 | 8.0-9.5 | |||

| 20 | 7.0-8.5 | |||

| 25 | 4.5-5.5 | |||

| 30 | 3.0-4.0 | |||

| 40 | 1.5-2.0 | |||

| 50 | 0.5-0.8 | |||

| 60 | 0.4-0.6 | |||

| 70 | 0.2-0.3 | |||

| 80 | 0.2-0.25 | |||

| 90 | 0.14-0.18 | |||

| 100 | 0.08-0.12 | |||

| 5 | 30.0-34.0 | 40000 | Air | |

| 6 | 25.0-30.0 | |||

| 8 | 22.0-25.0 | |||

| 10 | 17.0-23.0 | |||

| 12 | 13.0-16.0 | |||

| 14 | 12.0-14.0 | |||

| 16 | 9.0-11.5 | |||

| 18 | 8.0-10.0 | |||

| 20 | 7.0-9.0 | |||

| 25 | 5.0-5.5 | |||

| 30 | 3.5-4.5 | |||

| 40 | 1.7-2.2 | |||

| 50 | 0.7-1.0 | |||

| 60 | 0.4-0.6 | |||

| 70 | 0.3-0.4 | |||

| 80 | 0.25-0.3 | |||

| 90 | 0.2-0.25 | |||

| 100 | 0.15-0.2 |

Daya Ultra-Dhuwur (60000W) Parameter Pemotongan Stainless Steel

| Material | Kekandelan (mm) | Kacepetan (m/min) | Daya (watt) | Gas Kerja |

|---|---|---|---|---|

| Steel | 16 | 13.0-14.0 | 60000 | N₂ |

| 18 | 11.0-12.0 | |||

| 20 | 9.0-10.0 | |||

| 25 | 6.5-7.5 | |||

| 30 | 5.0-6.0 | |||

| 35 | 3.5-4.5 | |||

| 40 | 3.0-3.5 | |||

| 50 | 1.8-2.2 | |||

| 60 | 1.3-1.6 | |||

| 70 | 1.0-1.2 | |||

| 80 | 0.6-0.8 | |||

| 90 | 0.4-0.6 | |||

| 90 (Modulasi) | 0.2-0.25 | |||

| 100 | 0.3-0.5 | |||

| 100 (Modulasi) | 0.15-0.2 | |||

| 120 | 0.1-0.15 | |||

| 16 | 13-14.5 | 60000 | Air | |

| 18 | 11-12.5 | |||

| 20 | 9-10.5 | |||

| 25 | 7.0-7.8 | |||

| 30 | 5.0-6.0 | |||

| 35 | 4.0-4.5 | |||

| 40 | 3.2-4.0 | |||

| 50 | 3.0-3.5 | |||

| 60 | 1.8-2.2 | |||

| 70 | 1.0-1.2 | |||

| 80 | 0.7-0.8 | |||

| 90 | 0.5-0.6 | |||

| 100 | 0.4-0.5 | |||

| 120 | 0.25-0.35 | |||

| 150 | 0.15-0.2 | |||

| 200 (Modulasi) | 0.05-0.1 |

Fiber Laser Cutting Aluminium Ketebalan & Kacepetan & Power Chart

Aluminium minangka logam cahya perak-putih sing paling akeh, sing alus lan ulet.

Laser bisa gampang Cut liwat foil, sheets, ngudani, tabung, rod lan profil digawe saka aluminium lan wesi.

Sistem pemotongan laser serat becik kanggo nglereni aluminium sing digulung, aluminium tuang, campuran aluminium murni, paduan aluminium kanthi tembaga, mangan, silikon, magnesium lan seng nganti 100mm nglukis ing kacepetan maksimum 70m/ min, karo pilihan daya laser saka 1000W kanggo 40000W lan gas kerja N₂.

Daya Sedheng/Sedheng (1000W - 4000W) Parameter nglereni Aluminium

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| aluminium | N₂ | 1 | 10.0-13.0 | 15.0-27.5 | 22.0-31.0 | 25.0-30.0 | 28.0-32.0 |

| 2 | 2.0-4.5 | 7.0-8.6 | 10.0-13.2 | 15.0-18.0 | 16.0-20.0 | ||

| 3 | 0.6-1.3 | 2.5-4.0 | 5.0-6.6 | 7.0-8.0 | 10.0-12.0 | ||

| 4 | 1.0-1.6 | 1.5-2.2 | 5.0-6.0 | 6.0-7.0 | |||

| 5 | 0.6-0.9 | 1.0-1.3 | 2.5-3.0 | 4.0-5.0 | |||

| 6 | 0.6-0.9 | 1.5-2.0 | 2.5-3.0 | ||||

| 8 | 0.4-0.7 | 0.5-0.8 | 1.0-1.3 | ||||

| 10 | 0.3-0.4 | 0.8-1.0 | |||||

| 12 | 0.6-0.8 | ||||||

| 14 | 0.3-0.5 | ||||||

Daya dhuwur (6000W - 30000W) Parameter nglereni Aluminium

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| aluminium | N₂ | 1 | 35.0-45.0 | 40.0-50.0 | 45.0-55.0 | 50.0-60.0 | 55.0-65.0 | 60.0-70.0 |

| 2 | 20.0-25.0 | 25.0-30.0 | 30.0-35.0 | 35.0-38.0 | 40.0-45.0 | 45.0-50.0 | ||

| 3 | 14.0-16.0 | 15.0-23.0 | 20.0-25.0 | 25.0-30.0 | 30.0-35.0 | 38.0-45.0 | ||

| 4 | 8.0-10.0 | 12.0-16.0 | 18.0-20.0 | 20.0-23.0 | 25.0-30.0 | 28.0-35.0 | ||

| 5 | 5.0-7.0 | 7.0-10 | 14.0-16.0 | 15.0-18.0 | 18.0-20.0 | 20.0-25.0 | ||

| 6 | 3.5-4.0 | 5.0-7.0 | 10.0-12.0 | 12.0-14.0 | 16.0-18.0 | 18.0-22.0 | ||

| 8 | 1.5-2.0 | 2.5-4.0 | 6.0-8.0 | 8.0-10.0 | 10.0-13.0 | 14.0-18.0 | ||

| 10 | 1.0-1.2 | 2.0-2.5 | 4.0-6.0 | 5.0-7.0 | 9.5-10.0 | 12.0-15.0 | ||

| 12 | 0.6-0.7 | 1.6-2.0 | 2.0-3.0 | 2.5-3.5 | 5.0-6.0 | 10.0-12.0 | ||

| 14 | 0.4-0.6 | 0.8-1.2 | 1.5-2.5 | 2.0-3.0 | 4.5-5.0 | 8.0-10.0 | ||

| 16 | 0.3-0.4 | 0.8-1.0 | 1.3-2.0 | 1.5-2.5 | 3.0-4.0 | 6.0-8.0 | ||

| 20 | 0.5-0.7 | 0.8-1.2 | 0.8-1.2 | 1.6-2.0 | 2.0-3.0 | |||

| 25 | 0.4-0.5 | 0.5-0.7 | 0.5-0.7 | 1.0-1.2 | 1.5-2.0 | |||

| 30 | 0.4-0.5 | 0.45-0.6 | 0.8-1.0 | 1.0-1.2 | ||||

| 35 | 0.3-0.35 | 0.45-0.55 | 0.7-0.9 | 0.8-1.0 | ||||

| 40 | 0.25-0.3 | 0.28-0.33 | 0.4-0.7 | 0.5-0.8 | ||||

| 50 | 0.15-0.2 | 0.2-0.25 | 0.3-0.5 | 0.4-0.6 | ||||

| 60 | 0.2 | 0.2-0.3 | 0.25-0.35 | |||||

| 70 | 0.08-0.13 | 0.12-0.15 | ||||||

| 80 | 0.08-0.1 | |||||||

Daya Ekstra Dhuwur (40000W) Parameter nglereni Aluminium

| Material | Kekandelan (mm) | Kacepetan (m/min) | Daya (watt) | Gas Kerja |

|---|---|---|---|---|

| aluminium | 5 | 25.0-30.0 | 40000 | N₂ |

| 6 | 20.0-25.0 | |||

| 8 | 18.0-22.0 | |||

| 10 | 14.0-17.0 | |||

| 12 | 11.0-13.0 | |||

| 14 | 9.0-11.0 | |||

| 16 | 7.0-9.0 | |||

| 18 | 5.0-7.0 | |||

| 20 | 4.0-5.0 | |||

| 25 | 3.0-3.5 | |||

| 30 | 2.0-3.0 | |||

| 40 | 1.0-1.5 | |||

| 50 | 0.4-0.6 | |||

| 60 | 0.2-0.3 | |||

| 70 | 0.2-0.25 | |||

| 80 | 0.15-0.2 | |||

| 90 | 0.12-0.15 | |||

| 100 | 0.08-0.1 |

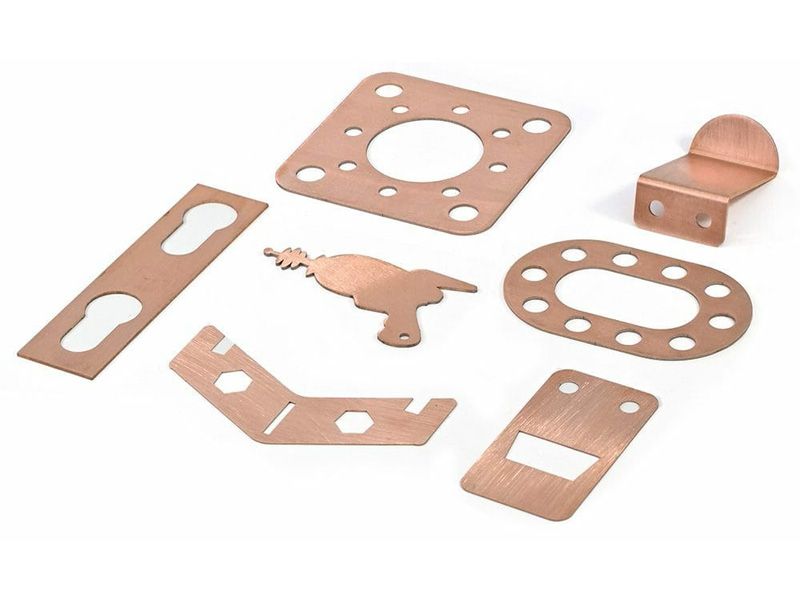

Serat Laser Cutting Kuningan & Tembaga Ketebalan & Speed & Power Chart

Tembaga minangka logam alus lan ulet kanthi konduktivitas listrik, konduktivitas termal, daktilitas, lan tahan korosi. Kuningan minangka paduan tembaga lan seng kanthi sifat mekanik sing dhuwur lan tahan nyandhang.

Laser bisa gampang Cut liwat kuningan kanggo nggawe instruments tliti, bagean kapal, komponen elektronik, meriam bedhil, alat musik, dekorasi, dhuwit recehan lan cetakan.

Saliyane tembaga lan kuningan biasa, laser serat uga nduweni kemampuan kanggo ngethok tembaga aluminium, tembaga mangan, kuningan aluminium, logam gun (perunggu timah-seng), tembaga putih lan paduan nikel-tembaga (Monel) kanthi ketebalan saka 1mm kanggo 80mm ing kacepetan saka 0.4m / min kanggo 65m / min, karo daya laser minangka kurang 1000W lan dhuwur minangka 40000W, nggunakake nitrogen kanggo Cut Kuningan lan oksigen kanggo Cut tembaga.

Daya Sedheng/Sedheng (1000W - 4000W) Parameter Pemotongan Kuningan

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | ||||

|---|---|---|---|---|---|---|---|

| 1000W | 1500W | 2000W | 3000W | 4000W | |||

| Kuningan | N₂ | 1 | 14.0-20.0 | 15.0-22.0 | 20.0-27.0 | 20.0-28.0 | 25.0-30.0 |

| 2 | 3.0-4.5 | 4.0-7.2 | 7.7-8.8 | 7.0-13.2 | 12.0-15.0 | ||

| 3 | 1.0-1.2 | 1.1-1.5 | 3.0-4.5 | 5.0-7.2 | 5.5-7.7 | ||

| 4 | 1.0-1.2 | 1.3-1.8 | 2.5-3.0 | 3.5-5.5 | |||

| 5 | 0.6-0.9 | 0.8-0.9 | 1.6-2.0 | 2.0-3.5 | |||

| 6 | 0.4-0.6 | 0.8-1.2 | 1.4-2.2 | ||||

| 8 | 0.3-0.4 | 0.8-1.0 | |||||

| 10 | 0.4-0.6 | ||||||

Daya dhuwur (6000W - 30000W) Parameter Pemotongan Kuningan

| Material | Gas | Kekandelan (mm) | Kacepetan (m/min) | |||||

|---|---|---|---|---|---|---|---|---|

| 6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

| Kuningan | N₂ | 1 | 30.0-40.0 | 35.0-45.0 | 38.0-50.0 | 40.0-55.0 | 45.0-60.0 | 55.0-65.0 |

| 2 | 15.0-18.0 | 25.0-27.0 | 30.0-35.0 | 32.0-37.0 | 35.0-40.0 | 38.0-45.0 | ||

| 3 | 12.0-14.0 | 15.0-18.0 | 18.0-22.0 | 20.0-24.0 | 25.0-28.0 | 28.0-33.0 | ||

| 4 | 8.0-10.0 | 10.0-12.0 | 15.0-18.0 | 16.0-19.0 | 19.0-22.0 | 22.0-26.0 | ||

| 5 | 5.0-5.5 | 7.0-9.0 | 12.0-15.0 | 13.0-16.0 | 17.0-19.0 | 18.5-22.0 | ||

| 6 | 3.2-3.8 | 6.0-6.5 | 7.0-10.0 | 9.0-11.0 | 12.0-15.0 | 15.0-18.0 | ||

| 8 | 1.5-1.8 | 2.5-3.0 | 5.5-6.5 | 6.0-8.0 | 8.0-10.0 | 10.0-15.0 | ||

| 10 | 0.8-1.0 | 1.0-1.5 | 3.5-4.7 | 5.0-6.0 | 7.0-8.0 | 8.0-10.0 | ||

| 12 | 0.6-0.7 | 0.8-1.2 | 1.8-2.0 | 2.0-2.2 | 2.5-3.5 | 5.0-8.0 | ||

| 15 | 0.6-0.7 | 1.0-1.2 | 1.3-1.4 | 1.8-2.0 | 2.5-4.5 | |||

| 18 | 0.5-0.7 | 0.8-1.2 | 0.8-1.3 | 1.3-1.8 | ||||

| 20 | 0.3-0.5 | 0.6-0.7 | 0.8-1.0 | 1.0-1.2 | ||||

| 25 | 0.4-0.6 | 0.7-0.9 | 0.8-1.0 | |||||

| 30 | 0.3-0.5 | 0.5-0.7 | 0.6-0.8 | |||||

| 40 | 0.4-0.5 | 0.5-0.65 | ||||||

| 50 | 0.4-0.5 | |||||||

Daya Ekstra Dhuwur (40000W) Parameter Pemotongan Kuningan & Tembaga

| Material | Kekandelan (mm) | Kacepetan (m/min) | Daya (watt) | Gas Kerja |

|---|---|---|---|---|

| Kuningan | 5 | 25.0-30.0 | 40000 | N₂ |

| 6 | 20.0-25.0 | |||

| 8 | 18.0-22.0 | |||

| 10 | 10.0-14.0 | |||

| 12 | 8.0-11.0 | |||

| 14 | 6.0-8.0 | |||

| 16 | 5.0-7.0 | |||

| 18 | 4.0-5.0 | |||

| 20 | 3.0-4.0 | |||

| 25 | 2.5-3.0 | |||

| 30 | 2.0-2.5 | |||

| tembaga | 3 | 20.0-25.0 | 40000 | O₂ |

| 4 | 18.0-20.0 | |||

| 5 | 15.0-18.0 | |||

| 6 | 10.0-15.0 | |||

| 8 | 6.0-10.0 | |||

| 10 | 2.0-3.5 | |||

| 12 | 2.0-2.5 | |||

| 14 | 1.5-2.0 | |||

| 16 | 1.0-1.5 | |||

| 20 | 0.6-1.0 |

Ing cendhak, serat laser bisa Cut liwat logam minangka lancip 1mm lan kandel minangka 100mm utawa liyane, ing kacepetan minangka alon minangka 0.05m/ min lan minangka cepet 100m/ min utawa liyane, karo daya laser kiro-kiro saka 1000W kanggo 60000W. Daya lan gas kerja sing beda bakal nyebabake macem-macem kekandelan lan kacepetan pemotongan.

Iku sing bakal dianggep

Mesin pemotong laser serat cukup kuat kanggo ngethok bahan logam populer kanthi gampang lan presisi, sanajan sawetara logam sing reflektif kayata aluminium, tembaga, lan kuningan. Nanging, rada angel ngethok logam mulia kayata emas lan perak. Iki mbutuhake nemokake opsi daya paling apik lan gas apa, lan nyetel kanggo nyetel tengen nglereni laser paramèter kanggo njaluk proyek rampung lancar lan supaya sampah rasah.

Yen sampeyan pengin nggunakake emas lan salaka kanggo ngethok ornamen, perhiasan, kerajinan lan hadiah sing apik banget, uga sawetara bagean lan aksesoris sing presisi, aja ragu-ragu takon. STYLECNCStaff teknis kanggo entuk solusi kanggo bisnis lan anggaran sampeyan.